Operational Excellence with OKRs: Guide + 12 Operations OKR Examples

Ensuring that operational processes run smoothly throughout the company and that the business grows sustainably is a mammoth task for operations teams. OKRs can help to maintain strategic focus in day-to-day operations, prioritize the right initiatives and achieve peak performance.

In this article, we explain how exactly OKRs can promote operational excellence and how to write good Operations OKRs. We not only provide tips, but also concrete examples from practice.

What you can expect:

- What is Operational Excellence?

- Why OKRs for Operational Excellence?

- How to write good Operations OKRs

- 12 examples of well-formulated Operations OKRs

- Conclusion: OKRs pave the way to excellence

What is Operational Excellence?

Simply put, Operational Excellence (OpEx) means developing a company operationally in such a way that it continuously improves its business processes in order to maximize efficiency, quality and customer satisfaction. All processes and systems are continuously optimized across the entire value chain - always with customer needs, quality and efficiency in mind. The aim is to maximize performance, productivity and competitiveness.

The concept goes back to the 1970s and Dr. Joseph Juran. It originally referred primarily to manufacturing processes, but was later generalized and is now applied to entire companies.

Basic principles for operational excellence

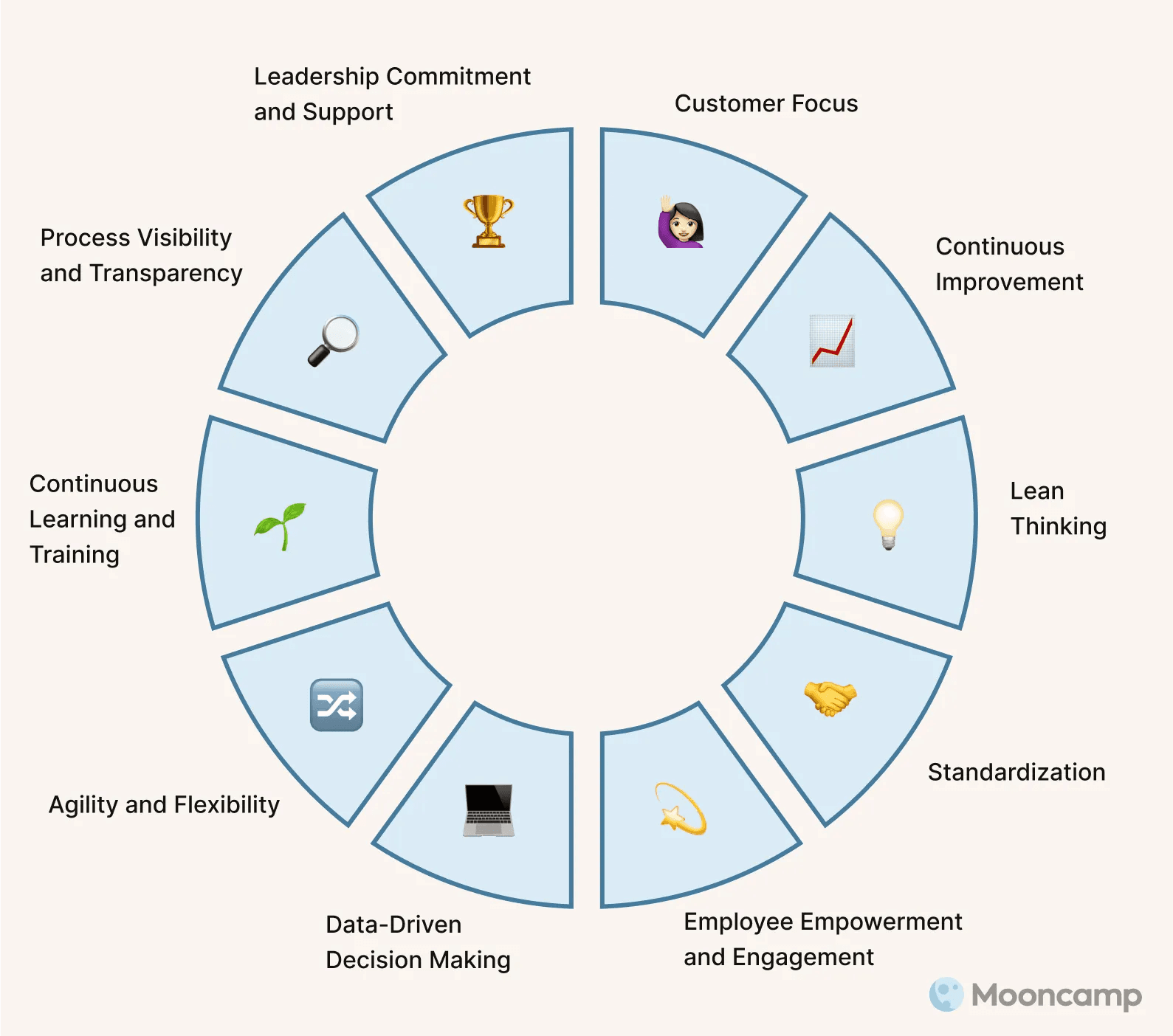

In practice, there are many different frameworks and methods for operational excellence - Lean, Six Sigma, Total Quality Management (TQM) and Kaizen are just a few examples. There is no single correct approach. Each company should choose the approach that best suits its individual needs and objectives.

However, there are some commonalities and essential topics in the approaches that can be summarized as basic principles for operational excellence:

Why OKRs for Operational Excellence?

Operational excellence is a never-ending process. Among other things, the operations team must identify inefficiencies, break down silos and streamline workflows. Short and medium-term improvements should always contribute to the company's long-term strategic goals.

It is therefore important to translate the overarching strategy into achievable, measurable goals, standardize processes and prioritize initiatives correctly - without restricting the company's flexibility and agility.

OKRs can help operations teams with this balancing act by

- focusing on the essentials,

- uncovering inefficiencies and dependencies,

- creating a shared understanding of success,

- aligning operational work with the corporate strategy,

- make progress and challenges visible and

- provide valuable data on productivity and efficiency.

💡 As a reminder: OKR (short for "Objectives and Key Results") is an agile framework for formulating and implementing strategic goals in companies that consists of three core elements:

- Objectives: What do I want to achieve?

- Key Results: How do I know that the objective has been achieved?

- Initiatives: How do I achieve the objective?

As a rule, 2 to 4 Objectives are formulated per team and 2 to 4 Key Results per Objective. The output is mapped in initiatives (= concrete activities). More basic knowledge can be found in our guide to the OKR method.

In general, OKRs focus on measurable results that bring real business benefits and put the customer's needs at the center. OKR check-ins during the cycle ensure that the teams can see transparently at any time who is working on what, what progress they are making towards their goals, where there may be problems or which initiatives are not working. This allows them to act based on data and adjust course quickly and flexibly if necessary. They can also use resources more efficiently.

In addition, the OKR framework is designed for continuous improvement: Each OKR cycle ends with an OKR Review, in which the content of the OKRs is evaluated. And in the OKR Retrospective, the entire process is methodically reflected upon once again and optimized for the next cycle.

The bottom line is that OKRs are structured from the ground up in such a way that they contribute to most of the basic principles of operational excellence. They link short and medium-term priorities with the overarching why. This ensures that the Operations team focuses on the processes and systems that are currently most relevant to strategy execution and require the most attention.

How to write good Operations OKRs

Operational teams usually work best with OKRs that they derive themselves bottom-up from the business objectives. After all, the employees involved in implementation are intimately familiar with the operational processes. They know what works, what challenges exist and where there is the greatest potential for improvement. This knowledge should definitely be incorporated into Operational Excellence OKRs. This ensures that they are tailored to the needs and realities of the team. This ultimately leads to more effective implementation and better results.

Basically, good Operations OKRs can be formulated in three steps:

1. Asking the right questions

To create OKRs for operational excellence, it is best to start with a retrospective and analyze the status quo - especially if you are working with OKRs for the first time. Before the OKR planning session, the answers to these questions should be clear:

- What problems have we already been able to solve in the last few months?

- What have we learned from them?

- What went well?

- Where should we improve?

- What points are still open?

2. Define thematic focus

Once you have worked out where the organization stands so far, the next step is to choose the right thematic focus for the current cycle. For operational excellence, for example, this could be

- Processes: Review systems as well as workflows and optimize them so that they function as efficiently as possible and are scalable.

- Quality: Maintain high quality standards and minimize errors.

- Resource management: Identify inefficiencies and allocate human, time and financial resources in a way that minimizes wasted resources.

- Collaboration and culture: Create alignment between teams to break down silos and build a culture based on collaboration, continuous improvement and empowerment.

- HR management: Motivate and continuously develop employees.

- Risk management: Minimize risks and ensure compliance.

It is best for operations teams to choose only two to three key topics per cycle so that the focus is on the most important things. Sometimes it even makes sense to formulate only one or two objectives per team and cycle.

The following questions can help to gain clarity about the most important open issues for the next cycle:

- Which key figures are we already tracking?

- Where are we not yet achieving the desired results?

- Are there processes that can be simplified or shortened?

- How are our throughput times?

- Are our employees motivated and satisfied? What about training and development?

- Are there initiatives that can improve our product or service?

3. Formulate OKRs

In the final step, the appropriate Objectives and Key Results must be formulated for the identified topics. A few (linguistic) rules must be observed here - otherwise there is a risk that the OKRs will not have the right focus (more on this in our articles on Aspirational vs. Committed OKRs and Output vs. Outcome) and the desired success will not materialize.

Basically, this rule applies to OKRs:

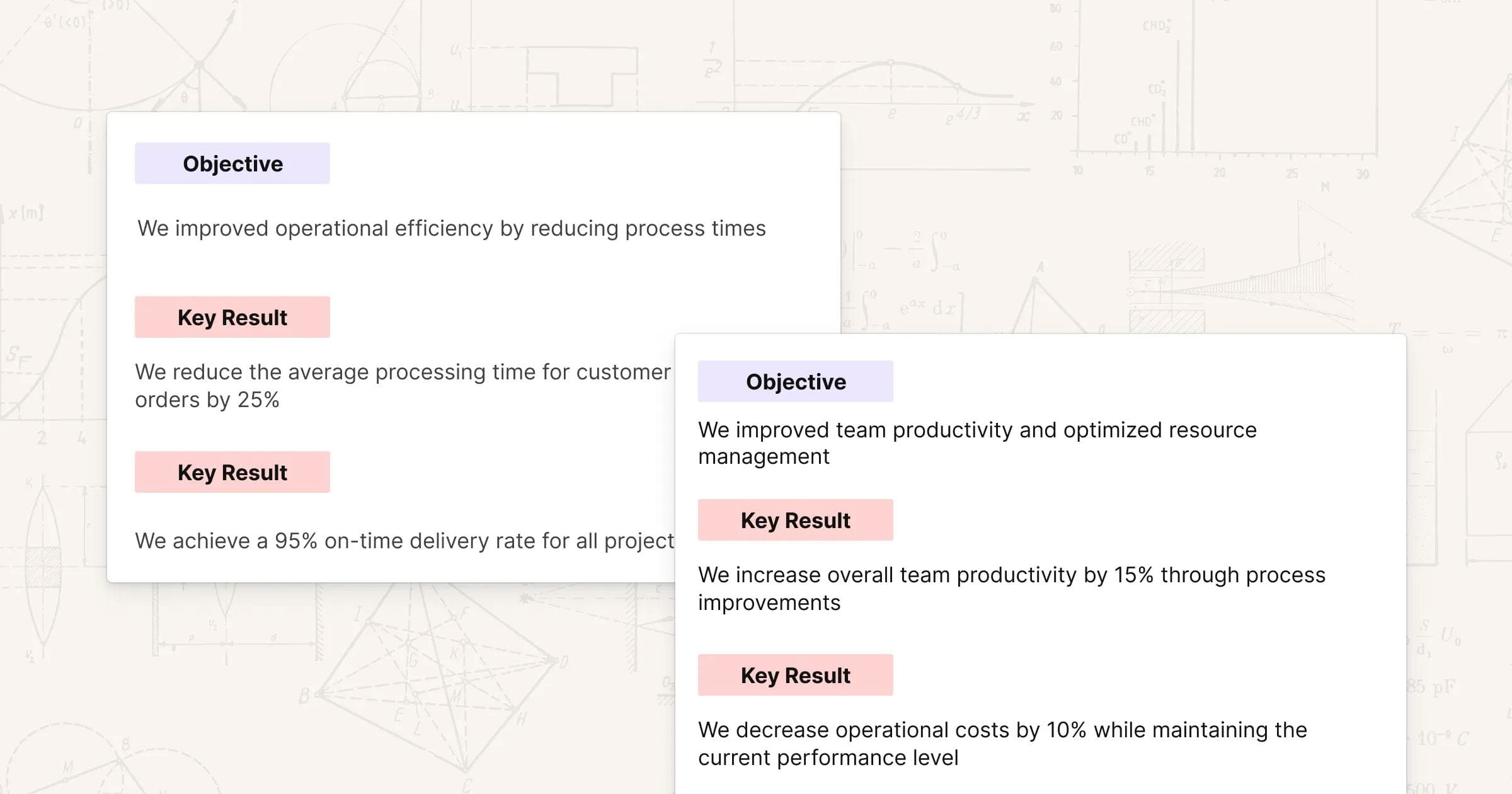

We will [Objective], as measured by [Key Results].

An Objective should always answer the question of what you want to achieve. It should always be formulated in a qualitative, easily understandable and inspiring way. The objectives should also be clearly aligned - for example with the company's OKRs or central KPIs.

Each individual Key Result then describes how to recognize that the Objective has been achieved. Key Results must therefore always have a direct link to the Objective. They should also be results-oriented and clearly measurable. The formulation should always contain exactly one key figure that covers the state targeted in the Objective as well as possible.

As an initial orientation, here are some suggestions for typical key figures in Key Results on the topic of operational excellence:

Focus area | Key figures examples |

|---|---|

Processes | Throughput times, delivery times, production capacity, number of completed projects |

Quality | Customer satisfaction (CSAT or NPS score), customer lifetime value (CLV), error rate, processing times |

Resource management | Resource utilization, inventory costs, overtime, idle time |

Collaboration and culture | e.g. team satisfaction, employee participation, communication frequency, conflicts between teams |

HR management | Employee satisfaction, employee retention, employee participation, turnover rate, results in performance evaluations |

Risk management | Number of security incidents, financial risk, compliance rate, response time to potential risks |

💡 Tip: All criteria for good Objectives and Key Results as well as general formulation tips can be found in our article "Formulating OKRs: How to write OKRs".

12 examples of Operations OKRs

To illustrate what this can look like in practice, we have put together some examples of well-formulated Operations OKRs.

💡 Note: Ultimately, you should always write your own OKRs. However, the examples here can serve as inspiration. You can find even more OKR examples for a wide variety of topics and teams on our website.

⚙️ Processes

🏆 Quality

🌱 Resource management

🤝 Collaboration and culture

☘️ HR management

🚨 Risk management

Conclusion: OKRs pave the way to excellence

To summarize: Operational excellence is not a static state, but rather an ongoing process of continuous improvement. Companies are constantly working to be operationally better than their competitors.

OKRs can help operations teams to align their efforts with the company's strategic goals. They ensure transparency, promote collaboration and focus on clearly measurable results. Overall, they support the continuous improvement process and pave the way to operational excellence.

How Mooncamp supports

An OKR software such as Mooncamp can also make things easier. Operations teams can use it to create OKRs quickly and keep a better eye on their progress in terms of excellence in their day-to-day work:

- It provides transparency and optimizes communication around OKRs. It serves as a central hub.

- OKRs are much easier to manage in OKR software than in Excel spreadsheets or misappropriated tools.

- Integrated check-ins and regular reminders ensure that all employees keep an eye on their OKRs and really work on them.

- Everyone has insight into progress at all times and can easily filter and analyze the data. This also allows strategic adjustments to be made quickly if necessary.